Back Back

Research Article

ScienceAsia 27 (2001) : 193-198 |doi: 10.2306/scienceasia1513-1874.2001.27.193

Hydrogen Production by Catalytic Ethanol Steam Reforming

Apichai Therdthianwong*, Tawee Sakulkoakiet and Supaporn Therdthianwong

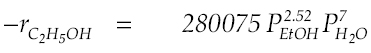

ABSTRACT: A new promising way to utilize the dilute solution of ethanol is the reforming process of ethanol to produce hydrogen gas that can then be passed through a molten carbonate fuel cell to generate electricity. In this research the rate expression for the ethanol steam reforming reaction at 400 and 650 oC under atmospheric pressure was attempted. The effect of temperature on reaction conversion was also studied. Experiments were conducted in a fixed bed reactor over Ni/Al2O3 catalyst. The experimental results show that as W/F ratio increases, the H2 yield increases for both reforming temperatures at 400 and 650 oC but at higher reforming temperature a certain W/F ratio (~ 6 gm cat.-hr/mole) is needed to maintain low CH4 yield. In addition thermal cracking reaction plays an important role at 650 oC. Therefore, the use of high temperature internal ethanol steam reformer in fuel cell is not practical and a pre-converter unit is recommended. The reaction rate obtained at 400 oC reaction temperature under atmospheric pressure is  . .

Download PDF

Chemical Engineering Practice School, Faculty of Engineering, King Mongkut’s University of Technology Thonburi, Bangkok 10140, Thailand.

* Corresponding author, E-mail: apichai.the@kmutt.ac.th

Received 9 Nov 1999, Accepted 20 Apr 2001

|